Glitter DTF Transfer Custom Gang Sheet

✨ 30% OFF – First Order Only ✨

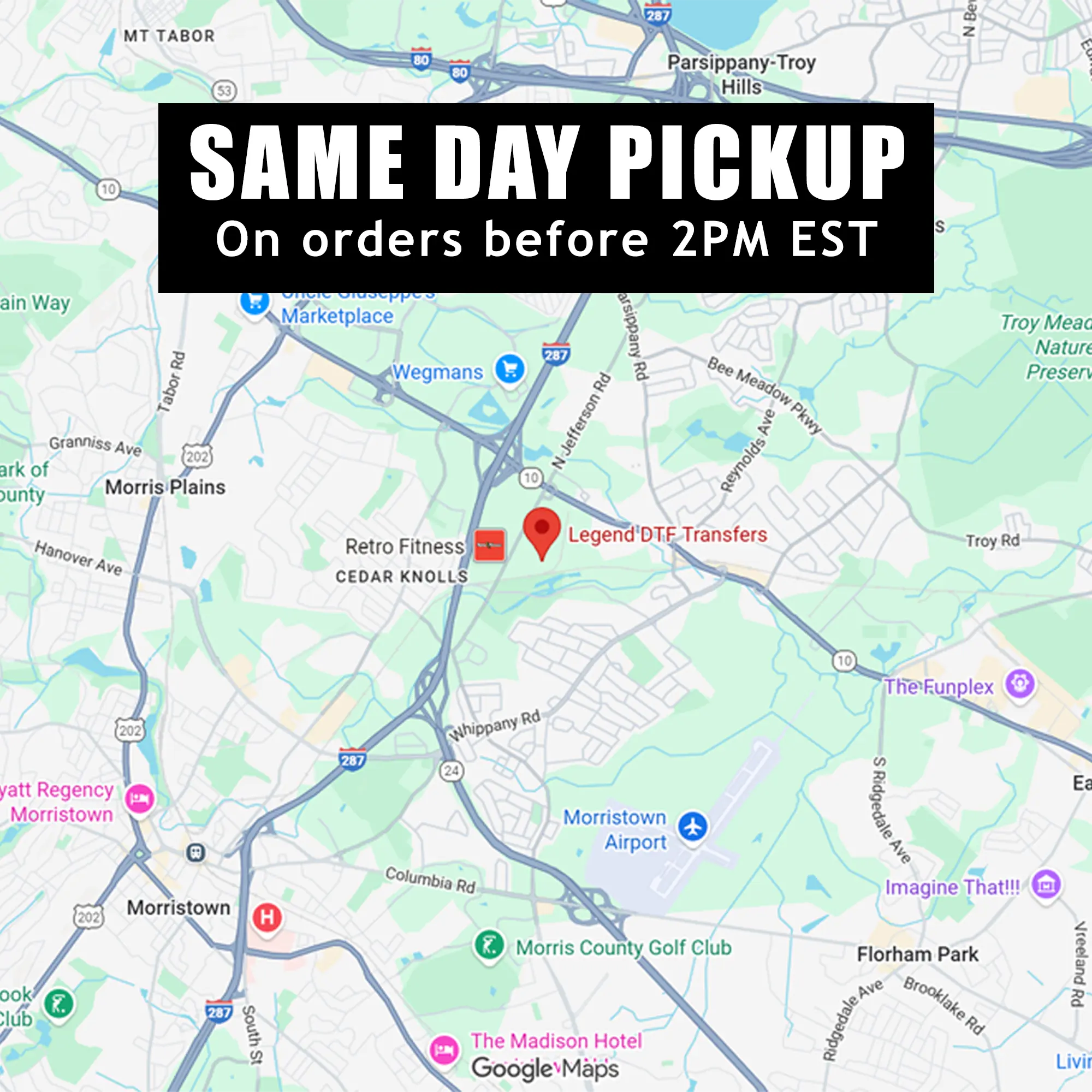

Pickup available at Legend Transfers Usually ready in 4 hours

Pickup available

-

Legend Transfers

Pickup available, usually ready in 4 hours

1 Apollo Drive

Check in google map

Unit D

Whippany NJ 07981

United States

Checkout with Paypal

Estimate delivery times: 3-6 days (United States).

Fast and Easy Pick-Up Service: Place your order for DTF and UV DTF prints, and pick them up at your convenience.

Guarantee Safe Checkout

Glitter DTF Transfer Custom Gang Sheet

Description

Glitter Gang Sheet Printing Guide

DTF Transfer Custom has quickly become one of the most popular methods in textile decoration. It is preferred for its bright colors, strong adhesion, and long-lasting quality. This technique works well on many fabric types, making it suitable for both small and large production needs.

One advanced option within this printing method is the glitter gang sheet system. It combines eye-catching sparkle effects with efficient layout planning. As a result, businesses can lower costs, speed up production, and create visually striking apparel.

This guide explains how glitter gang sheets work, where they are used, and why they are a smart choice for custom textile printing.

What Is DTF Transfer Custom?

DTF Transfer Custom refers to transfer prints created based on specific customer requirements. Designs can be adjusted in size, color, and placement before printing. Once prepared, they are transferred onto fabric using heat and pressure.

This approach gives full control over the final result. It is widely used by brands, print shops, and online sellers who need flexibility and consistent quality. Custom transfers are especially useful for mixed orders and personalized designs.

What Is a Glitter Gang Sheet?

A glitter gang sheet is a single transfer film that includes multiple glitter designs arranged together. Instead of printing each design on a separate film, everything is combined on one sheet.

The glitter layer adds shine and texture, helping designs stand out on garments. At the same time, the shared layout reduces film waste and improves production efficiency. This makes the method ideal for bulk orders and varied design collections.

Benefits of Glitter Gang Sheet Printing

Cost Efficiency

-

Less film consumption

-

Better use of ink and materials

-

Lower cost per design

Faster Production

-

Multiple designs printed in one run

-

Fewer print cycles

-

Shorter turnaround times

Strong Visual Appeal

-

Glitter finish adds sparkle

-

Premium look on apparel

-

Ideal for branding and promotions

Flexible Use

-

Different sizes on one sheet

-

Suitable for many products

-

Easy order combination

These advantages make glitter gang sheets a reliable solution for modern printing needs.

How the Printing Process Works

Design Setup

Artwork is prepared using graphic design software. All designs are placed on one canvas. Proper spacing and sizing are important to avoid errors during transfer.

Printing Stage

The completed layout is printed onto special transfer film. Glitter ink or glitter powder is used to achieve the shiny effect.

Adhesive Application

A heat-activated adhesive powder is applied evenly. This layer ensures strong bonding between the design and the fabric.

Heat Press Transfer

The sheet is pressed onto the garment using heat and pressure. After pressing, the film is peeled according to the film type.

Where Glitter Transfers Are Commonly Used

This printing method works well across many industries.

Apparel Printing

-

T-shirts

-

Hoodies

-

Sweatshirts

-

Tote bags

Promotional Products

-

Event merchandise

-

Branded clothing

-

Campaign apparel

Fashion and Retail

-

Streetwear brands

-

Custom collections

-

Limited-edition designs

Glitter finishes are especially popular for bold, creative, and high-impact products.

Tips for High-Quality Results

To achieve professional output, consider the following tips:

-

Use high-resolution artwork

-

Avoid very small glitter details

-

Match colors with fabric tones

-

Choose quality film and adhesive powder

-

Follow recommended heat and pressure settings

Good preparation improves both durability and appearance.

Common Problems and Solutions

Glitter Peeling

-

Cause: Low heat or weak adhesive

-

Solution: Increase press temperature and use quality materials

Uneven Shine

-

Cause: Uneven powder application

-

Solution: Apply adhesive evenly across the design

Color Variations

-

Cause: Incorrect printer settings

-

Solution: Calibrate the printer before production

Why Choose Custom Glitter Transfers?

DTF Transfer Custom solutions offer full control over layout and design. When combined with glitter effects, they deliver strong visual impact without sacrificing efficiency.

This method is ideal for businesses that want:

-

Custom layouts

-

Premium finishes

-

Cost-effective production

Conclusion

The glitter gang sheet method is a powerful option for modern textile printing. It combines visual appeal with smart production planning. By placing multiple glitter designs on one transfer film, businesses can save time, reduce waste, and deliver standout products.

With the right setup and quality materials, results remain vibrant, durable, and professional.

Follow Legend Transfers

Stay updated on custom transfer and glitter printing solutions:

Product Features

Efficient High-Volume DTF Gang Sheet Printing

Our DTF gang sheets allow you to combine multiple designs,logos, labels, or custom artwork onto a single large-format sheet. Perfect for streamlined production and cost-effective bulk printing.

Versatile Size Options

Choose from the industry-standard 22” width, with customizable lengths ranging from 24” to 240” or more. Ideal for small business needs or high-volume production runs.

Print-Ready File Required

For fast and accurate results, your file must be fully arranged, sized, and spaced exactly as you want it printed. File editing is not performed unless requested as an additional service.

Premium DTF Print Quality

Our expert team and high-end equipment deliver vivid colors, high resolution, soft feel, excellent stretch, and durability up to 60+ washes. Professional quality you can rely on.

No Minimums – Order What You Need

Whether you need a single sheet or hundreds, our modern facility in New Jersey is fully equipped to fulfill your order efficiently at any scale.

Same-Day Printing – Local Pickup Available

Place your order by 12 PM ET for same-day production. Enjoy fast local pickup at our Denville, NJ location or choose nationwide shipping across the U.S.

Upload Recommendations

Accepted File Types

Please upload your artwork in PNG (preferred) or PDF format. If transparency is required, make sure the background is transparent.

👉 Do not upload multiple separate files — all designs must be pre-arranged into a single gang sheet file before submission.

Resolution

Files must be created at a minimum of 300 DPI to ensure high print quality.

Low-resolution artwork may result in blurred or pixelated prints, and we are not responsible for poor output due to insufficient resolution.

Print-Ready Format

We do not edit, resize, or rearrange your designs.

Please ensure your file is fully prepared and ready for print. Double-check all spelling, colors, positioning, and alignment before uploading.

Bleed & Spacing

Leave at least 0.25” (¼ inch) of spacing between each design to allow room for cutting or trimming.

We do not automatically separate or cut your gang sheet unless the "pre-cut" option is selected during checkout.

Size Match

Your uploaded file must match the exact dimensions of the gang sheet size you selected (e.g., 22” x 60”).

Files that do not match may be rejected or automatically scaled, which could lead to image distortion.

Size & Arrangement Tips

Sheet Width

All gang sheets are printed at a fixed width of 22 inches.

You choose the length — common options include 24", 48", 60", or custom lengths up to 240".

Your Responsibility: Layout Preparation

You are fully responsible for how your artwork is arranged on the sheet.

We do not reposition, organize, or adjust the placement of your designs.

Please use design tools such as Photoshop, Illustrator, Canva, or a gang sheet builder to prepare your layout before uploading.

Design Scaling

Each design element must be already scaled to its intended print size.

For example, if you want a logo printed at 3" x 3", it should appear at exactly that size within the file you upload.

Pro Tip: Optimize Your Layout

To maximize space and minimize waste, group similar-sized items together or align repeating elements (like logos or labels) efficiently.

Smart layout saves money and improves production speed.

Pressing Instructions

How to Apply Your Gang Sheet Transfers

Follow these verified steps for optimal results when applying your DTF gang sheet transfers:

1. Cut and Prepare

Carefully trim around each design using scissors or a cutting mat, or select the pre-cutting option at checkout if available.

2. Apply Heat

: 300–320°F (150–160°C)

: 7–12 seconds

: Medium to firm

Use parchment paper or a Teflon sheet to protect the design during pressing.

Apply even pressure to fully activate the adhesive and ensure a strong bond.

3. Peel Film

Peel the carrier sheet either immediately after pressing or once fully cooled — both methods are supported and yield excellent results.

No waiting time is required before washing, allowing faster production.

Optional: Repress for Finish

For a smoother, matte finish and added durability, repress using parchment paper for an additional 5 seconds.

⚠️ Pro Tip: Always run a test press on sample fabric before bulk application to verify optimal settings for your garments.