DTF Transfers by Piece - By Size

✨ 30% OFF – First Order Only ✨

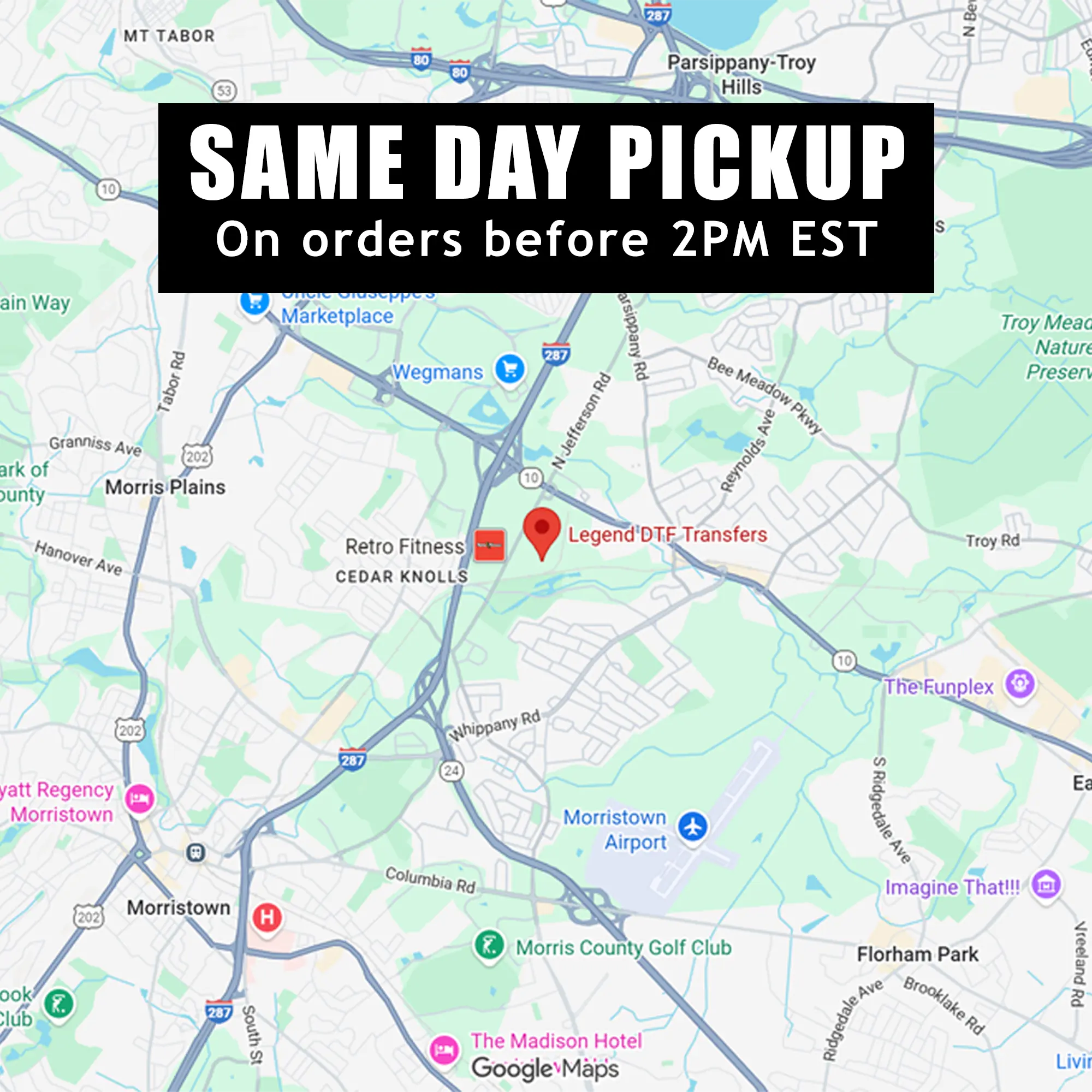

Pickup available at Legend Transfers Usually ready in 24 hours

Pickup available

-

Legend Transfers

Pickup available, usually ready in 24 hours

1 Apollo Drive

Check in google map

Unit D

Whippany NJ 07981

United States

Checkout with Paypal

Estimate delivery times: 3-6 days (United States).

Fast and Easy Pick-Up Service: Place your order for DTF and UV DTF prints, and pick them up at your convenience.

Guarantee Safe Checkout

DTF Transfers by Piece - By Size

Description

Product Features

Efficient High-Volume DTF Gang Sheet Printing

Our DTF gang sheets allow you to combine multiple designs,logos, labels, or custom artwork onto a single large-format sheet. Perfect for streamlined production and cost-effective bulk printing.

Versatile Size Options

Choose from the industry-standard 22” width, with customizable lengths ranging from 24” to 240” or more. Ideal for small business needs or high-volume production runs.

Print-Ready File Required

For fast and accurate results, your file must be fully arranged, sized, and spaced exactly as you want it printed. File editing is not performed unless requested as an additional service.

Premium DTF Print Quality

Our expert team and high-end equipment deliver vivid colors, high resolution, soft feel, excellent stretch, and durability up to 60+ washes. Professional quality you can rely on.

No Minimums – Order What You Need

Whether you need a single sheet or hundreds, our modern facility in New Jersey is fully equipped to fulfill your order efficiently at any scale.

Same-Day Printing – Local Pickup Available

Place your order by 12 PM ET for same-day production. Enjoy fast local pickup at our Denville, NJ location or choose nationwide shipping across the U.S.

Upload Recommendations

Accepted File Types

Please upload your artwork in PNG (preferred) or PDF format. If transparency is required, make sure the background is transparent.

👉 Do not upload multiple separate files — all designs must be pre-arranged into a single gang sheet file before submission.

Resolution

Files must be created at a minimum of 300 DPI to ensure high print quality.

Low-resolution artwork may result in blurred or pixelated prints, and we are not responsible for poor output due to insufficient resolution.

Print-Ready Format

We do not edit, resize, or rearrange your designs.

Please ensure your file is fully prepared and ready for print. Double-check all spelling, colors, positioning, and alignment before uploading.

Bleed & Spacing

Leave at least 0.25” (¼ inch) of spacing between each design to allow room for cutting or trimming.

We do not automatically separate or cut your gang sheet unless the "pre-cut" option is selected during checkout.

Size Match

Your uploaded file must match the exact dimensions of the gang sheet size you selected (e.g., 22” x 60”).

Files that do not match may be rejected or automatically scaled, which could lead to image distortion.

Size & Arrangement Tips

Sheet Width

All gang sheets are printed at a fixed width of 22 inches.

You choose the length — common options include 24", 48", 60", or custom lengths up to 240".

Your Responsibility: Layout Preparation

You are fully responsible for how your artwork is arranged on the sheet.

We do not reposition, organize, or adjust the placement of your designs.

Please use design tools such as Photoshop, Illustrator, Canva, or a gang sheet builder to prepare your layout before uploading.

Design Scaling

Each design element must be already scaled to its intended print size.

For example, if you want a logo printed at 3" x 3", it should appear at exactly that size within the file you upload.

Pro Tip: Optimize Your Layout

To maximize space and minimize waste, group similar-sized items together or align repeating elements (like logos or labels) efficiently.

Smart layout saves money and improves production speed.

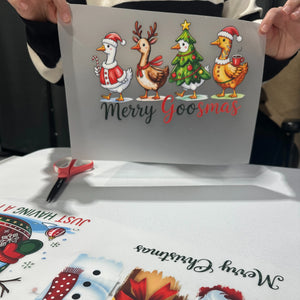

Pressing Instructions

How to Apply Your Gang Sheet Transfers

Follow these verified steps for optimal results when applying your DTF gang sheet transfers:

1. Cut and Prepare

Carefully trim around each design using scissors or a cutting mat, or select the pre-cutting option at checkout if available.

2. Apply Heat

: 300–320°F (150–160°C)

: 7–12 seconds

: Medium to firm

Use parchment paper or a Teflon sheet to protect the design during pressing.

Apply even pressure to fully activate the adhesive and ensure a strong bond.

3. Peel Film

Peel the carrier sheet either immediately after pressing or once fully cooled — both methods are supported and yield excellent results.

No waiting time is required before washing, allowing faster production.

Optional: Repress for Finish

For a smoother, matte finish and added durability, repress using parchment paper for an additional 5 seconds.

⚠️ Pro Tip: Always run a test press on sample fabric before bulk application to verify optimal settings for your garments.