Filter

Sort by:

Custom UV DTF Transfers

Custom UV DTF Transfers: An In-Depth Guide

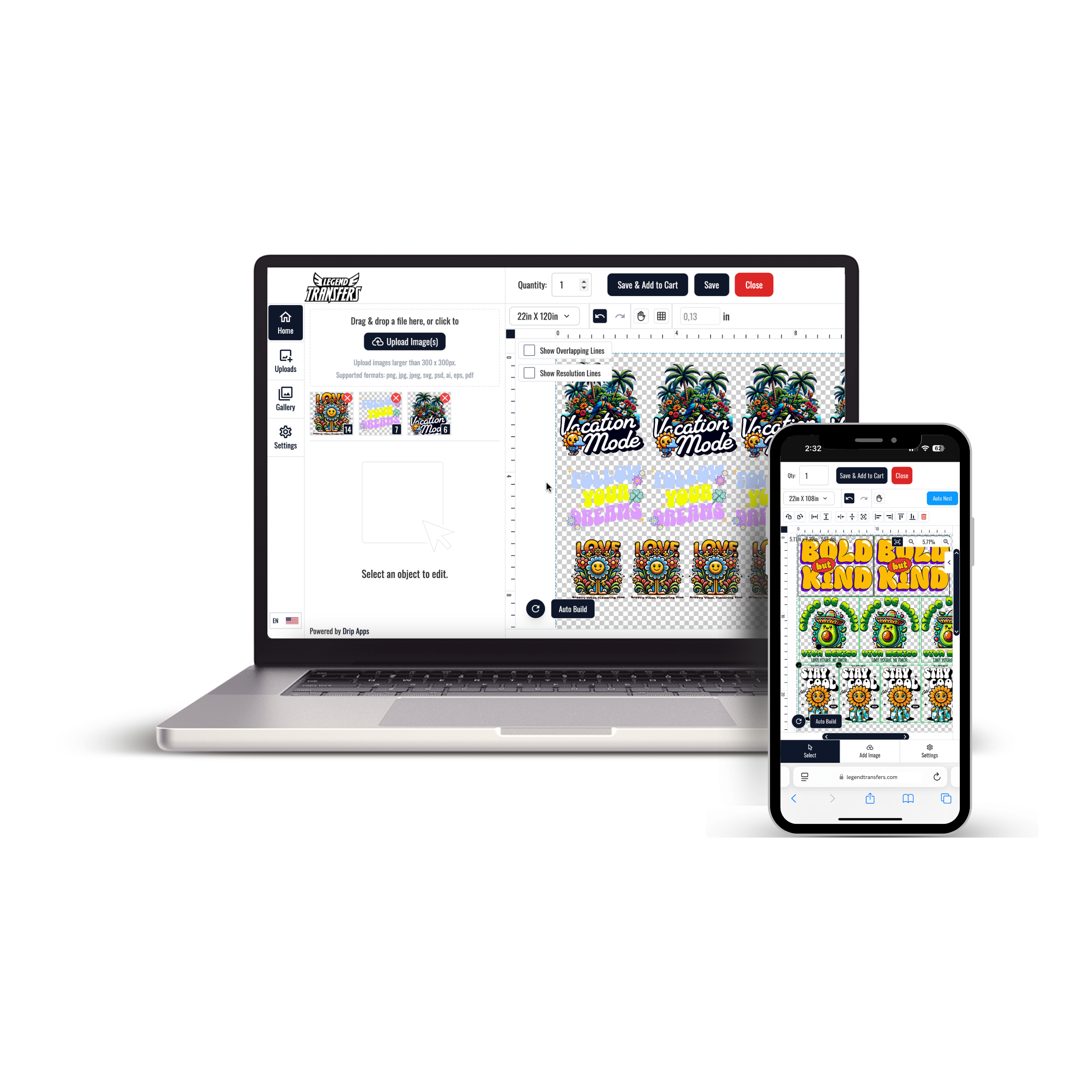

Custom UV DTF (Direct to Film) transfers are revolutionizing the customization industry with their versatility and vibrant, durable prints. This unique printing method offers high-quality graphics that adhere to various materials, from fabrics to hard surfaces, allowing creators, businesses, and DIY enthusiasts to produce personalized products with ease.

What Are Custom UV DTF Transfers?

UV Direct-to-Film Transfers combine two advanced technologies—UV printing and DTF transfer techniques—to deliver a vivid, long-lasting print. In UV printing, ultraviolet light cures the ink immediately upon application, ensuring a sharp and precise print. DTF transfer technology, on the other hand, involves printing a design onto a special film, which is then transferred to the desired surface through a heat press.

This fusion allows for a seamless application of high-resolution graphics with intricate details and vibrant colors. Whether you're looking to customize clothing, phone cases, mugs, or any other hard surfaces, UV DTF transfers can handle it.

Key Benefits of Custom UV DTF Transfers

-

Vivid Colors and Fine Details

- UV printing technology ensures that each design maintains its vibrancy and clarity, making it ideal for high-quality artwork and detailed logos.

-

Durability

- The UV-cured ink and DTF’s heat-activated adhesive result in a print that’s resistant to fading, scratching, and peeling. This durability is especially valuable for items subjected to frequent washing or handling.

-

Versatility Across Surfaces

- Unlike other transfer methods, UV Direct-to-Film Transfers work effectively on both soft and hard materials. From textiles to glass, metal, and plastic, these transfers are adaptable.

-

Eco-Friendly

- UV inks are typically free from volatile organic compounds (VOCs), making UV DTF transfers a more eco-conscious choice compared to some traditional printing methods.

-

No Need for Pretreatment

- For many surfaces, no pretreatment is required, simplifying the customization process and saving time for both hobbyists and professionals.

How Custom UV DTF Transfers Work

The UV Direct-to-Film Transfer process involves several steps to ensure a flawless result:

-

Design Creation

- First, you create a digital design, whether it’s artwork, text, or a logo. The design is prepared with UV-compatible colors and resolution for optimal print quality.

-

Printing onto Film

- The design is printed directly onto a transparent DTF film using UV ink. Ultraviolet light instantly cures the ink, locking it in place and preserving the colors and details.

-

Applying Adhesive Powder

- A special adhesive powder is applied to the printed side of the film. This powder will melt during the heat press stage, allowing the design to adhere firmly to the target surface.

-

Heat Press Transfer

- The film is placed onto the item, and a heat press activates the adhesive, transferring the design permanently. Once cooled, the film is removed, leaving a crisp, vibrant design.

Applications of UV Direct-to-Film Transfers

UV Direct-to-Film Transfers are suitable for a wide array of applications, including:

- Apparel: Customize t-shirts, hoodies, hats, and other garments with intricate designs.

- Accessories: Personalize items like phone cases, water bottles, and laptop covers.

- Home Decor: Add designs to decorative pieces, ceramics, and glassware.

- Marketing Materials: Create branded items, from promotional giveaways to high-quality merchandise.

Choosing the Right UV DTF Transfer for Your Needs

When selecting a UV Direct-to-Film Transfer service or equipment, consider the following factors:

- Print Quality: Look for high-resolution capabilities to ensure clarity in your designs.

- Adhesive Strength: Ensure the adhesive powder is suitable for your intended material, especially for non-porous surfaces.

- UV Ink Quality: High-quality UV inks contribute to durability and color fidelity.

- Ease of Use: If you plan to create transfers yourself, look for user-friendly equipment with straightforward settings.

Maintenance and Care

To maximize the longevity of items customized with UV DTF transfers, consider the following care instructions:

- Wash with Care: For apparel, wash items inside out on a gentle cycle to reduce wear on the design.

- Avoid Harsh Chemicals: Avoid using abrasive cleaners or chemicals on hard surfaces to preserve the design’s integrity.

- Store Properly: Keep items away from excessive heat and direct sunlight to maintain color vibrancy.

Conclusion

UV Direct-to-Film Transfers offer a unique blend of flexibility, durability, and vibrancy, making them an ideal choice for anyone looking to personalize a wide range of items. By leveraging the precision of UV printing with the adaptability of DTF transfer technology, creators can achieve impressive results across multiple surfaces. As this technology continues to evolve, UV Direct-to-Film Transfers are set to become a staple in the world of custom printing and design.

Click here for Wikipedia