Start Your Own Clothing Brand with Heat Transfer Prints

Starting your own clothing brand can be an exciting venture. One great way to make your brand stand out is by using heat transfer prints. This technique lets you create unique, custom designs on garments, including t-shirts, hoodies, and more. In this guide, we will explore the benefits of heat transfer printing. We will also cover its different techniques and explain why it’s an excellent choice for your clothing brand.Start Your Own Clothing Brand with Heat Transfer Prints and create high-quality, customized apparel that will set your brand apart.

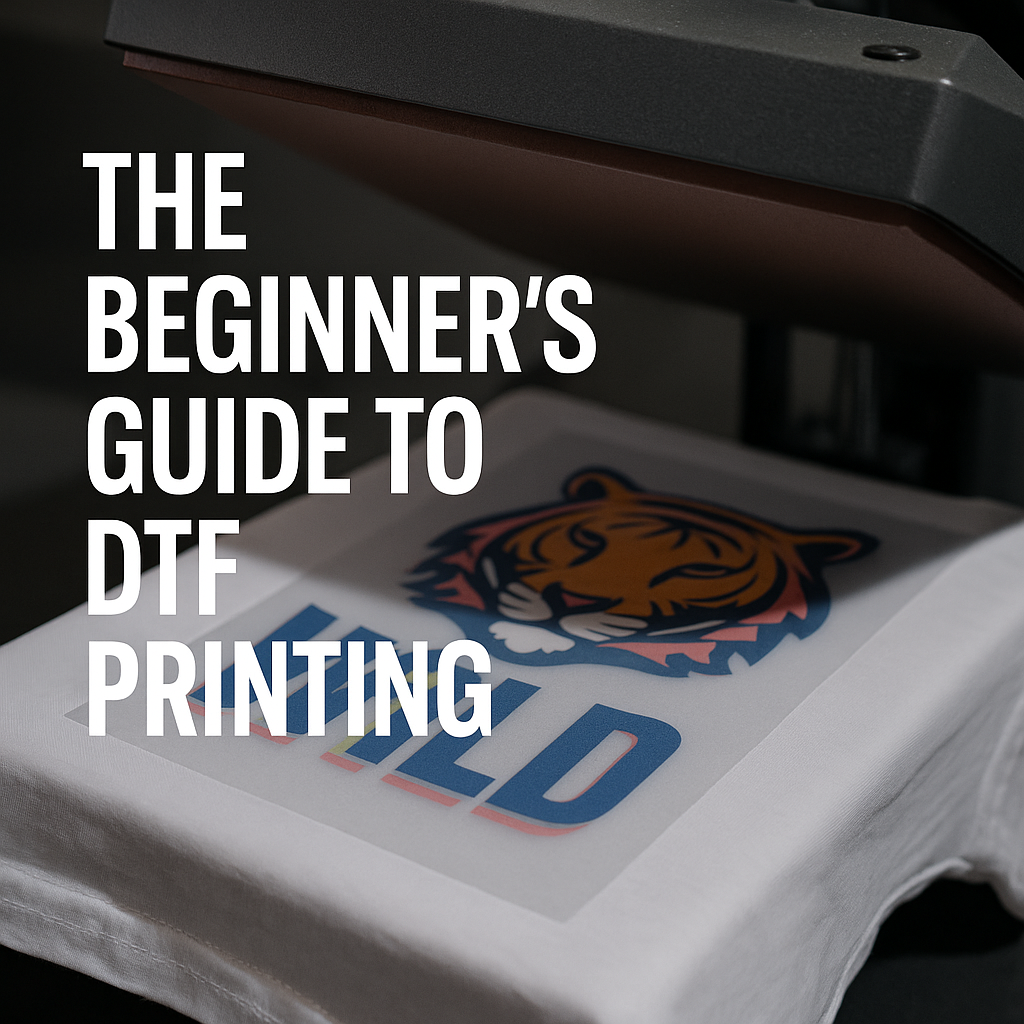

What is Heat Transfer Printing?

Heat transfer printing is a method where designs are printed onto transfer paper. The design is then transferred to fabric using heat. First, the image is printed on special transfer paper. Then, the design is applied to the garment using a heat press. The high heat activates the adhesive in the transfer paper, bonding the design to the fabric.

Benefits of Heat Transfer Printing

Heat transfer printing offers several advantages for clothing brands, especially those just starting. Some of the key benefits include:

-

Cost-Effective: Unlike traditional methods, heat transfer printing doesn’t require expensive setup costs. This makes it more affordable for small businesses.

-

Flexibility: You can print custom heat transfer prints on a wide range of garments, including t-shirts, hats, and jackets.

-

Quick Turnaround: Heat transfer printing is faster than other methods. This allows for quick production and delivery.

-

High-Quality Results: Printed heat transfers offer vibrant colors and detailed designs. They can last through multiple washes.

Heat Transfer Printing Techniques

There are several heat transfer printing techniques to bring your designs to life. These include:

-

Vinyl Heat Transfers: This technique uses vinyl sheets to create custom designs. The vinyl is cut into shapes or letters and then applied to the garment using a heat press.

-

Sublimation Heat Transfers: Sublimation uses heat to turn ink into gas. The gas bonds directly with the fibers of the fabric. This technique works best on polyester and synthetic fabrics, producing vibrant and long-lasting designs.

-

Plastisol Transfers: Plastisol ink is printed onto transfer paper. It is then transferred to the garment using heat. This method is ideal for dark-colored fabrics.

-

Foil Heat Transfers: This method applies shiny metallic foil over a printed design. It creates a reflective finish that adds an eye-catching touch to your designs.

How Heat Transfer Printing Works

The process of heat transfer printing starts with creating a digital design. The design is printed onto special transfer paper. You can use a regular inkjet printer for sublimation heat transfers or a printer with heat transfer paper for vinyl heat transfers. The transfer paper is then placed onto the garment. A heat press applies pressure and heat to bond the design to the fabric. This process leaves a clean, professional finish. Start your own clothing brand with heat transfer prints and enjoy the benefits of a cost-effective, efficient, and high-quality printing method.

Choosing the Right Heat Transfer Printing Method for Your Clothing Brand

Choosing the right heat transfer printing method depends on several factors. Here’s how to decide:

-

Fabric Type: Certain methods work better with specific fabrics. For example, sublimation works best on polyester, while vinyl is great for cotton fabrics.

-

Design Complexity: If you have intricate designs, printed heat transfers might be the best option. It captures fine details and vibrant colors.

-

Quantity: For bulk orders, heat transfer printing can be faster and more cost-effective than screen printing.

Heat Transfer Print Durability

One of the reasons heat transfer prints are so popular is their durability. When applied correctly, the design lasts through multiple washes without fading, cracking, or peeling. To ensure longevity, follow proper heat press guidelines. Use high-quality transfer papers and inks.

Heat Transfer Printing vs. Screen Printing

While screen printing is popular for larger runs, heat transfer printing offers several advantages for small businesses and custom clothing brands:

-

No Minimum Order: Unlike screen printing, which often requires a minimum order, heat transfer printing is ideal for small runs and custom designs.

-

Less Setup Time: Heat transfer printing does not require creating screens or stencils, reducing setup time and costs.

-

More Design Freedom: With heat transfer printing, you can print intricate designs with full color. Screen printing may be limited by color or design complexity.

Creating Custom Designs with Heat Transfers

One of the best aspects of heat transfer printing is its ability to easily customize designs. You can create custom heat transfer prints for your brand. This allows you to feature logos, artwork, or personalized messages. Whether you want to print text, images, or both, heat transfer printing gives you full control over the design and its application.

Why Choose Heat Transfer Printing for Your Clothing Brand?

Heat transfer printing is an excellent choice for starting your own clothing brand for several reasons:

-

Cost-Effective Solutions: It’s an affordable way to produce high-quality garments without investing in expensive equipment or inventory.

-

Fast Production: Heat transfer printing enables quick turnaround times, making it perfect for fulfilling customer orders on time.

-

Customization: You can offer a wide range of custom options, including personalized designs, making your clothing brand stand out.

-

Quality: Heat transfer printing ensures your designs are vibrant, durable, and professionally applied. Your customers will love the high-quality products.

Common Applications for Heat Transfer Prints

Heat transfer prints can be used for various products and industries. Some common applications include:

-

Custom Apparel: T-shirts, hoodies, sweatshirts, and caps are ideal for heat transfer prints.

-

Promotional Products: Bags, jackets, and hats make great promotional items, as they can be easily customized with logos and messages.

-

Sports Team Uniforms: Heat transfer printing is great for adding team names, logos, and player numbers to uniforms.

Tips for Starting Your Own Clothing Brand with Heat Transfer Prints

If you are looking to start your own clothing brand using heat transfer prints, here are a few tips to get started:

-

Invest in Quality Equipment: A good heat press machine and high-quality transfer papers are essential for achieving professional results.

-

Design Your Brand: Spend time creating your brand’s identity, including logo, colors, and designs that will resonate with your target audience.

-

Choose the Right Materials: Select fabrics that work well with heat transfer printing. Cotton and polyester are commonly used for this method.

-

Offer Unique Designs: Stand out by offering custom designs that appeal to your niche market. You can offer personalized prints for special events or create limited edition items.

-

Focus on Marketing: Use social media platforms to promote your clothing brand, showcase your heat transfer prints, and engage with your audience.

Conclusion

Start Your Own Clothing Brand with Heat Transfer Prints is a great way to enter the fashion and custom apparel industry. The flexibility, cost-effectiveness, and quality of heat transfer printing allow you to produce high-quality, customized garments that stand out. By choosing the right printing method and following best practices, you can create unique designs that will help your brand thrive in the competitive market. Start your own clothing brand with heat transfer prints and enjoy the ability to offer customers unique, personalized products while keeping costs low and production efficient. Whether you're starting small or planning for large-scale production, heat transfer printing provides an accessible and reliable solution for your clothing business.

FOR DETAILED INFORMATION, CLICK ON WIKIPEDIA

Explore our DTF Gang Sheet for high-quality printing solutions